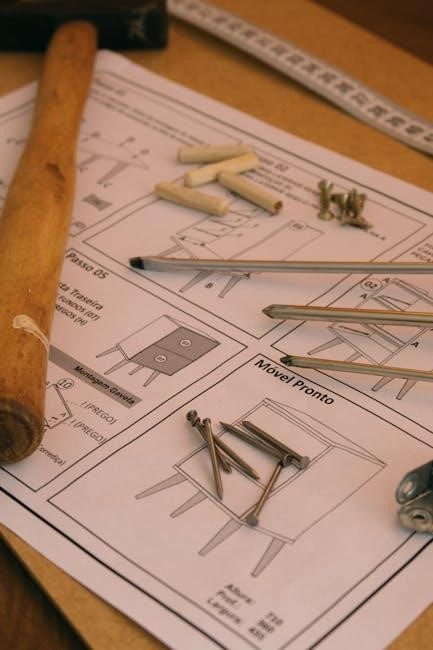

RTA (Ready-to-Assemble) cabinets offer a cost-effective, DIY-friendly solution for kitchen and bathroom renovations. This guide provides step-by-step instructions for assembling base and wall cabinets, ensuring a smooth process.

What Are RTA Cabinets?

RTA (Ready-to-Assemble) cabinets are pre-manufactured cabinet units that require assembly before installation. They are typically shipped flat in boxes, containing all necessary components like panels, shelves, and hardware. RTA cabinets are cost-effective and ideal for DIY projects, offering customization options to fit various spaces. They are commonly used in kitchens and bathrooms, providing a practical solution for homeowners seeking to save money without compromising on quality and style.

Why Follow Assembly Instructions?

Following RTA cabinet assembly instructions ensures a successful and safe installation. Proper assembly prevents structural issues, misalignment, and potential damage to components. Clear step-by-step guides help DIYers avoid common mistakes, saving time and effort. Adhering to instructions also guarantees stability and functionality, making the cabinet durable and secure. This careful approach ensures the final product meets quality standards and enhances overall satisfaction with the renovation project.

Key Components of RTA Cabinet Assembly

RTA cabinet assembly involves several essential components, including the cabinet box, shelves, drawers, and hardware like screws, hinges, and drawer glides. The back panel and stretchers provide structural support, while doors and handles complete the exterior. Proper alignment and secure fastening of these parts ensure stability and functionality. Understanding each component’s role is crucial for a successful assembly process and a durable, long-lasting cabinet system.

Gathering Materials and Tools

Gathering materials and tools is crucial for efficient RTA cabinet assembly. Collect all hardware, components, and tools like screwdrivers and wrenches. Prepare a workspace for assembly.

Essential Tools for Assembly

The essential tools for RTA cabinet assembly include a screwdriver, Allen wrench, hammer, clamps, and tape measure. These tools ensure proper alignment and secure fastening of components. Additional items like safety goggles and a rubber mallet may be useful for protecting surfaces and preventing damage. Having all tools ready before starting ensures a smooth and efficient assembly process without delays.

Required Hardware and Fasteners

RTA cabinet assembly requires specific hardware, including screws, bolts, cam locks, and dowels. These fasteners ensure secure connections between panels and components. Shelf clips, hinges, and handles are also essential for functionality. Make sure to use the hardware provided in the kit, as substitutions may compromise stability. Always refer to the assembly manual for precise hardware requirements, ensuring proper installation and safety. This step is crucial for achieving a durable and functional cabinet structure.

Protective Gear and Workspace Preparation

Before starting assembly, ensure a safe working environment. Wear protective gear like gloves and safety glasses to prevent injuries. Clear a large, sturdy work surface and cover it with cardboard or a protective mat to avoid damage. Organize tools and hardware within easy reach. Proper lighting is essential for clarity. A well-prepared workspace minimizes risks and ensures efficient assembly. Safety and organization are key to a successful RTA cabinet assembly experience.

Understanding the Assembly Process

Understanding the assembly process is crucial for successful RTA cabinet assembly. It involves organizing tools, following clear instructions, and ensuring all hardware is ready. This systematic approach ensures a smooth and efficient assembly experience.

Reading the Instructions Carefully

Reading the instructions carefully is the foundation of a successful RTA cabinet assembly. Take the time to review each step, ensuring you understand the process before starting. Pay attention to diagrams and component labels to avoid confusion. Highlight or underline key steps to keep track of your progress. Double-checking instructions helps prevent mistakes, such as misaligning panels or using incorrect hardware. A thorough review ensures a smooth assembly process and a professional finish.

Identifying Cabinet Components

Identifying cabinet components is crucial for efficient assembly. Start by unpacking and organizing all parts, including side panels, back panels, shelves, drawer glides, and hardware. Refer to the provided parts list to ensure nothing is missing. Familiarize yourself with each component’s purpose, such as stretchers for stability or shelf clips for securing shelves. Proper identification prevents errors and ensures a smooth assembly process. Always cross-reference components with the instructions to confirm their correct placement and use.

Following Step-by-Step Guidelines

Following step-by-step guidelines ensures accurate and efficient assembly. Begin by organizing all components and tools, then proceed in the sequence outlined in the instructions. Start with assembling the cabinet box, ensuring panels are properly aligned and secured. Use screws and fasteners as directed, and cross-reference diagrams for clarity. Avoid skipping steps or over-tightening, as this may damage components. Complete each stage before moving to the next to maintain stability and alignment throughout the process.

Assembling Base Cabinets

Begin by preparing the cabinet box, then install drawer glides and shelves. Secure the back panel and stretchers for stability, ensuring proper alignment before proceeding.

Preparing the Cabinet Box

Begin by clearing a flat workspace and unpacking all components. Inspect the cabinet box for damage and ensure all parts are included. Organize hardware and tools, such as screwdrivers and rubber mallets. Align the side panels with the back panel, ensuring proper fitment. Use clamps to hold components in place before securing with screws. This step is crucial for maintaining structural integrity and ensuring a stable base for the cabinet.

Installing Drawer Glides and Shelves

Position the drawer glides on the inner walls of the cabinet box, aligning them with pre-drilled holes. Secure using screws provided. Place shelves inside, ensuring they fit snugly into shelf clips. Adjust shelves to desired heights and tighten clips firmly. Double-check alignment to ensure smooth drawer operation and level shelving. Proper installation guarantees functionality and durability for years to come.

Securing the Back Panel and Stretchers

Attach the back panel to the cabinet box using screws, ensuring it aligns flush with the edges. Next, install stretchers front-to-back and side-to-side, fitting them into the dadoes of the side panels. Tighten all connections firmly to stiffen the structure and ensure the cabinet is square. This step is crucial for maintaining stability and preventing warping during use. Properly secured stretchers and a back panel provide a solid foundation for shelves and drawers.

Assembling Wall Cabinets

Begin by preparing the wall cabinet box, ensuring all panels are aligned properly. Secure the sides, top, and bottom using the provided screws. Install wall brackets for mounting, following the manufacturer’s guidelines for safe and level installation. This step ensures the cabinet is sturdy and ready for final hardware installation.

Preparing the Wall Cabinet Box

Start by unpacking and inspecting all components of the wall cabinet box; Ensure all panels, shelves, and hardware are included and undamaged. Carefully align the side panels with the top and bottom panels, verifying proper fitment. Use the provided screws to secure the assembly, tightening firmly but avoiding overtightening. Double-check that all edges are flush and the structure is square before proceeding to the next steps.

Installing Wall Brackets and Supports

Begin by identifying the wall bracket locations on the cabinet box, ensuring they align with the manufacturer’s specifications. Carefully attach the brackets to the back panel using the provided screws, making sure they are flush with the cabinet edges. Next, install the supports or mounting rails, securing them firmly to the brackets. Double-check the alignment and tighten all connections to ensure stability and proper weight distribution for safe installation.

Securing the Doors and Hardware

Attach the hinges to the door and align them with the hinge plates on the cabinet frame. Carefully mount the doors, ensuring proper alignment and spacing. Install the handles or knobs according to the manufacturer’s specifications, tightening all screws securely. Adjust the hinges to achieve optimal door closure and alignment. Double-check all hardware for stability and functionality before finalizing the installation. Properly secured doors and hardware ensure durability and ease of use for your RTA cabinets.

Advanced Assembly Topics

Explore advanced techniques for customizing your RTA cabinets, such as installing Lazy Susan, corner solutions, and roll-out trays for enhanced functionality and storage.

Installing Lazy Susan and Corner Solutions

Begin by preparing the Lazy Susan unit according to the manufacturer’s instructions. Attach the turntable base to the cabinet floor using screws. Ensure proper alignment and stability. For corner solutions, measure and mark the installation points carefully. Secure the rotating shelves or baskets to the base, ensuring smooth rotation. Tighten all fasteners firmly. Finally, test the functionality by rotating the Lazy Susan and checking its stability.

Adding Roll-Out Trays and Special Features

Start by identifying the desired location for the roll-out tray or special feature within the cabinet. Measure the interior dimensions to ensure proper fit. Attach the necessary slides or brackets to the cabinet walls using screws. Align the tray or feature with the slides, ensuring smooth operation. Secure it firmly and test the roll-out mechanism. For special features like spice racks or wine holders, attach them to the designated areas using provided hardware. Double-check alignment and stability to prevent interference with other cabinet components. Follow manufacturer instructions for specific installation details to ensure functionality and longevity.

Final Adjustments and Alignment

After assembling the cabinet, ensure all components are securely fastened and properly aligned. Check drawer glides, shelves, and doors for smooth operation. Adjust hinges and drawer slides as needed to achieve proper alignment. Verify that all panels are flush and gaps are minimal. Tighten any loose joints and ensure the cabinet is level. Double-check hardware installation and make final adjustments to ensure stability and functionality. This step ensures the cabinet operates smoothly and maintains its structural integrity.

Troubleshooting Common Issues

Identify misaligned panels, loose joints, or hardware installation errors. Check for proper alignment, tighten joints, and verify hardware placement. Consult the manual for specific solutions to ensure stability and functionality.

Dealing with Misaligned Panels

Misaligned panels can compromise the structural integrity of your RTA cabinet. To address this, ensure all components are properly aligned before securing them with screws. Use a level to verify evenness and check the fit of doors and drawers. If panels shift during assembly, gently adjust them and tighten fasteners firmly. For persistent misalignment, consider using shims or repositioning brackets to achieve proper alignment and stability.

Fixing Loose Joints and Gaps

Tighten all screws and bolts to ensure stability. For persistent gaps, apply wood glue or use shims to align surfaces properly. Reinforce joints with additional brackets if necessary. Ensure all panels fit snugly before final tightening to maintain structural integrity and a polished appearance.

Solving Hardware Installation Problems

If hardware doesn’t fit, check alignment and orientation. Use correct screw sizes to avoid stripping threads. For misaligned pre-drilled holes, adjust slightly or use wood filler. Ensure all brackets and hinges are securely fastened. Refer to the instruction manual for specific hardware recommendations and troubleshooting tips to achieve a proper and functional installation.

Inspect all assembled cabinets for stability, alignment, and proper hardware installation. Test drawers and doors for smooth operation. Ensure all safety measures are met before use.

Inspecting the Assembled Cabinet

Inspect the cabinet for any gaps or misalignments. Ensure all panels are securely attached and properly aligned. Check for loose joints or uneven surfaces. Verify that all hardware, such as screws and brackets, is tightly fastened. Make sure the cabinet is level and plumb. Inspect drawers and shelves for correct installation and alignment. Ensure all doors and hinges are properly secured and functioning smoothly. Address any issues before finalizing the assembly.

Testing Drawers and Doors

Test drawers by sliding them in and out to ensure smooth operation. Check that doors open and close properly, aligning with the cabinet frame. Verify that all hinges and drawer glides function correctly. Make sure drawers are level and doors are evenly spaced. If necessary, adjust hinges or glides for proper alignment. Ensure there are no obstructions hindering movement. Repeat the process for all drawers and doors to confirm reliable functionality and ease of use.

Ensuring Stability and Safety

Ensure the cabinet is stable by installing stretchers front to back and securing the back panel tightly with screws. Check that all shelves and drawers are level and properly aligned. Verify that weight limits for shelves are not exceeded. Tighten all fasteners to prevent loose joints. Anchor wall cabinets to the wall for added stability. Double-check that all hardware is installed correctly to avoid hazards. Ensure the workspace is clear of debris for safe usage and maintenance.